Rudd Racing Engines

Six Shooter Showdown

Hill Country Performance: Building an engine for Compressed Air Supercharging

Click on image to read the complete article in Engine Builder Magazine

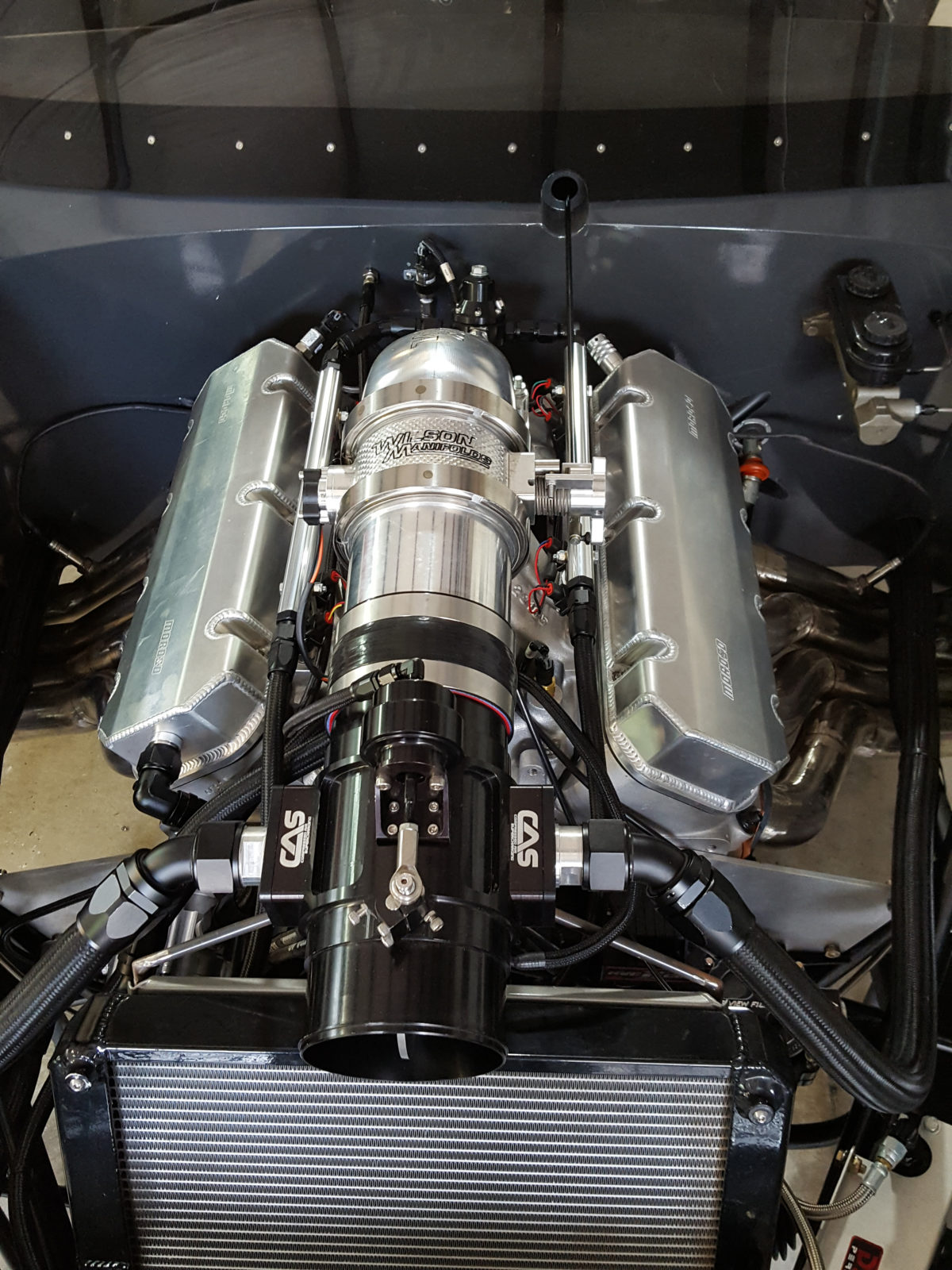

Engine and System Install

Two 158 scf carbon fiber cylinders were mounted between the tubs which is integrated into the rear chassis structure. Diesel exhaust stack mounting brackets which are attached to main chassis members

The two carbon fiber/aluminum cylinders were connected to the dual outlet port Mechanical regulator via a high pressure WYE Block and special high pressure low temperature hoses made by Kongsberg. The regulator was mounted in close proximity to the cylinders, while allowing the high pressure hose(s) to be routed so as not to put excessive side/bending load on the hose.

A high pressure 3-way valve is used to allow in-car refilling of the high pressure cylinders and to allow evacuating the system when not in use.

Each of the outlets of the dual port regulator were connected to a shut-off valve and electronic pressure regulator.

The electronic boost controller operates the shut-off valves and the electronic pressure regulator which allows for fully programable boost at any RPM.

One of many 4.50’s with a something

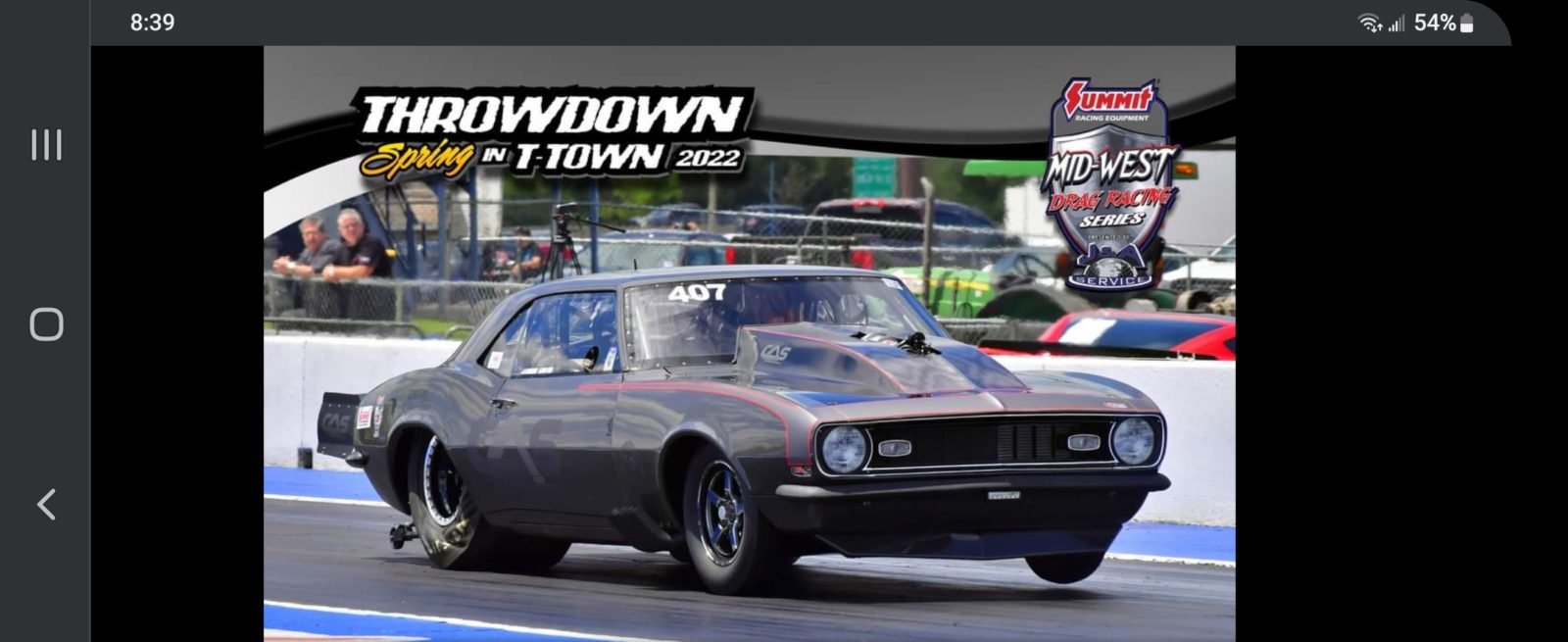

Throw Down in T-Town